Over 10 years of experience in creative Ultrasonic solutions!

SPECIALIST IN CUSTOM

MACHINE CONSTRUCTION

Before and after situations

A clear difference

So the difference between before and after cleaning with an ultrasonic cleaner is clearly noticeable. Before cleaning, a surface can look dirty and soiled, while after cleaning it looks much cleaner and shinier. Moreover, cleaning with an ultrasonic cleaner can be an effective and efficient way to remove even stubborn contaminants without the need for harsh chemicals.

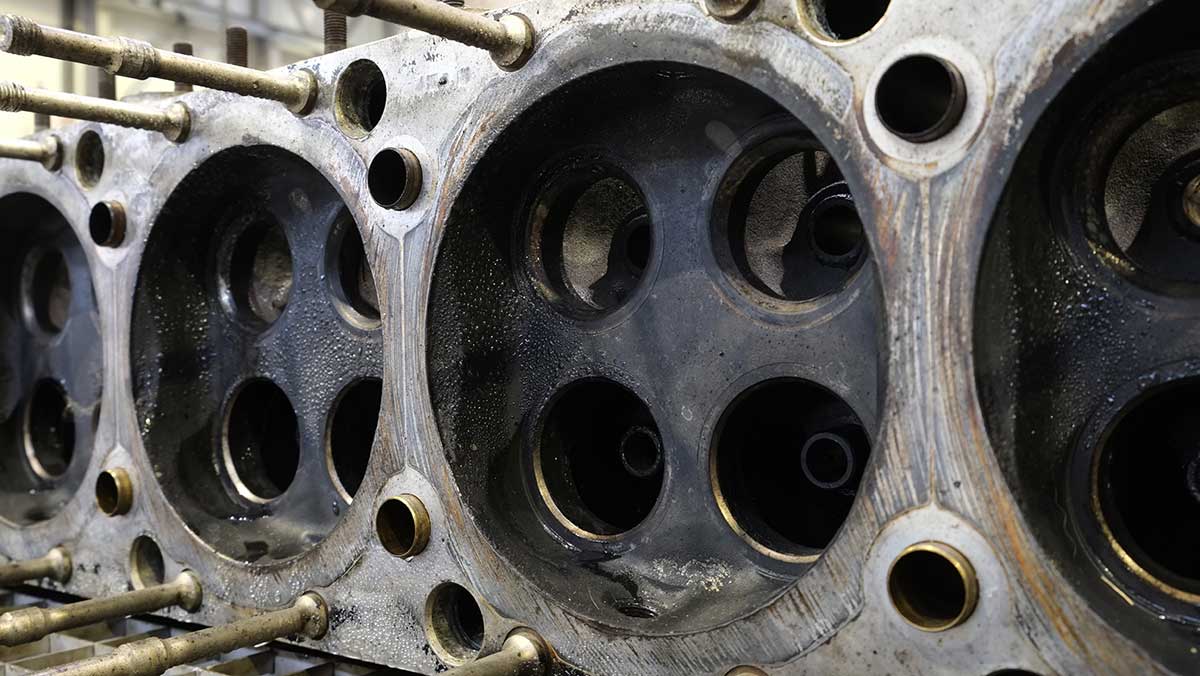

Situation before ultrasonic cleaner

A cylinder head can be seriously contaminated with carbon residue, oil, grease, etc.

Cleaning with an ultrasonic cleaner is an excellent solution for this.

Situation before ultrasonic cleaner

An injection mold can have stubborn contamination that conventional cleaning can only remove meganically. This can cause permanent damage to the mold.

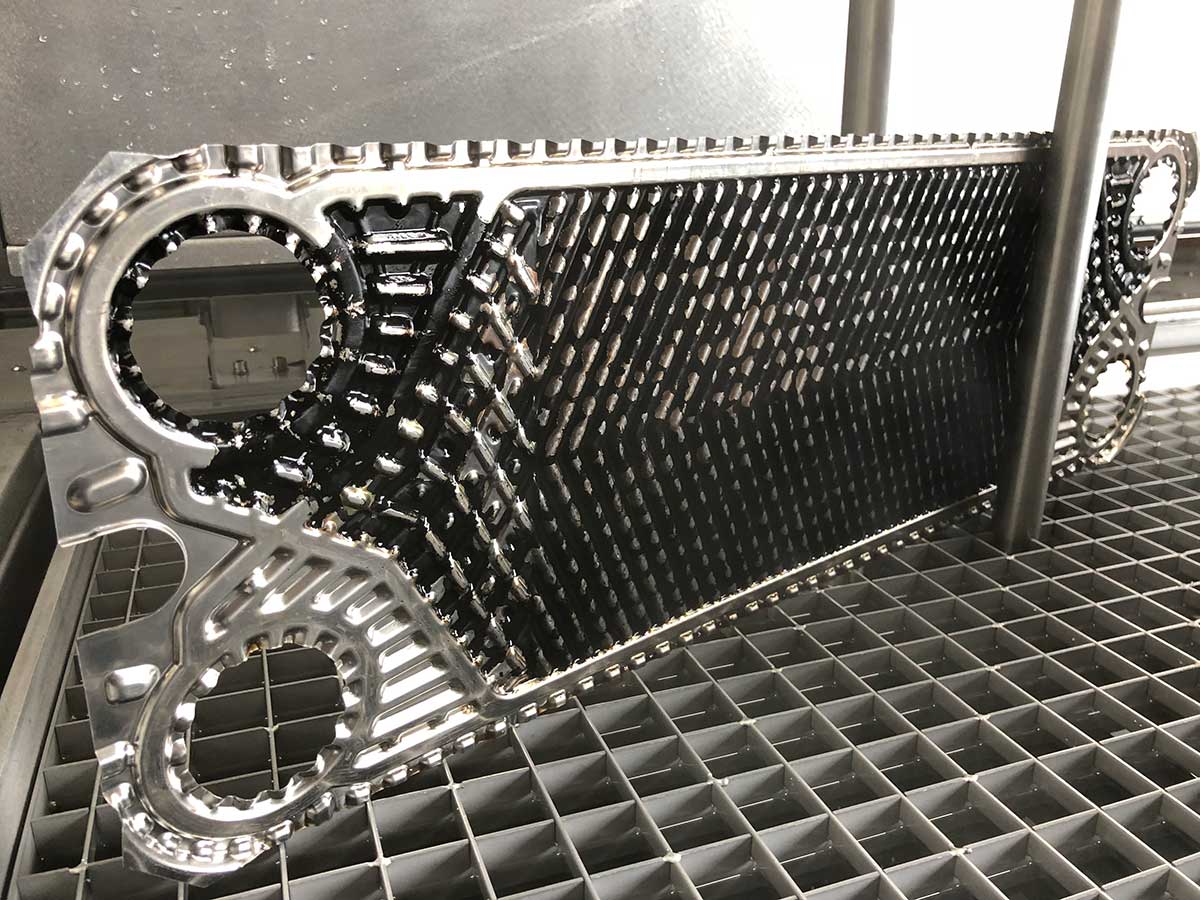

Situation before ultrasonic cleaner

The plates of heat exchangers are usually cleaned mechanically or specially developed cleaning agents are used, which is often environmentally damaging.

Situation before ultrasonic cleaner

Removing contamination on non-ferrous metals requires special attention and should be done with care. Mechanical cleaning quickly results in damage, and chemicals must also be handled with care.

Situation before ultrasonic cleaner

Large and heavy parts are often a very time-consuming and therefore costly job that often involves several people. Also, several cleaning processes are often necessary to achieve a good result.