ProSonic

Top-loading laundry cabinets

Wash cabinets X51 series

Compact and multifunctional. These are our stainless steel spray washers with a rotating basket up to a diameter of 1,295mm and maximum load of 350kg. With a maximum adjustable temperature up to 60°C, you degrease all visible surfaces at the push of a button.

Continuing with sustainability, ProSonic's spray washers come standard with a water storage tank, tank heater, oil skimmer and filter. This allows you to reuse the water containing the soap until its action diminishes.

Depending on the object and model of the spray washer, position the object one or more times for the most optimal cleaning.

Are you dealing with objects with hard-to-reach surfaces or hidden rooms? Then also inquire about our ultrasonic baths for immersed cleaning techniques.

L101

Description:

- Made of AISI 304 stainless steel

- Basket diameter Ø910mm up to 200kg

- Rotating basket, water propelled

- Electric heater, temperature adjustable up to 60°C

- Easily adjustable cleaning timer

- Circulating spray cleaning, 170L per minute

- 3 phase N+G, 400V

Optional:

- Oil skimmer with drain connection

- Vapor extraction after cleaning

- Removable basket on trolley

- Motorized basket rotation

- Automatic water and soap refill system

- Thermal insulation for longer temperature maintenance

L102

Description:

- Made of AISI 304 stainless steel

- Basket diameter Ø910mm up to 200kg

- Rotary basket, motorized

- Electric heater, temperature adjustable up to 60°C

- Easily adjustable cleaning timer

- Circulating spray cleaning, 2x 110L per minute

- 3 phase N+G, 400V

Optional:

- Oil skimmer with drain connection

- Vapor extraction after cleaning

- Removable basket on trolley

- Automatic water and soap refill system

- Thermal insulation for longer temperature maintenance

- Dirty water discharge pump

L122

Description:

- Made of AISI 304 stainless steel

- Basket diameter Ø1,150mm up to 350kg

- Rotary basket, motorized

- Electric heater, temperature adjustable up to 60°C

- Easily adjustable cleaning timer

- Circulating spray cleaning, 2x 160L per minute

- 3 phase N+G, 400V

Optional:

- Oil skimmer with drain connection

- Vapor extraction after cleaning

- Removable basket on trolley

- Motorized basket rotation

- Automatic water and soap refill system

- Thermal insulation for longer temperature maintenance

- Dirty water discharge pump

L152

Description:

- Made of AISI 304 stainless steel

- Basket diameter Ø1,295mm up to 350kg

- Rotary basket, motorized

- Electric heater, temperature adjustable up to 60°C

- Easily adjustable cleaning timer

- Circulating spray cleaning, 2x 200L per minute

- Pneumatic operation of the top lid

- 3 phase N+G, 400V

Optional:

- Oil skimmer with drain connection

- Vapor extraction after cleaning

- Removable basket on trolley

- Motorized basket rotation

- Automatic water and soap refill system

- Thermal insulation for longer temperature maintenance

- Dirty water discharge pump

ProSonic builds and installs machines in all markets!

The sectors in which our customers operate are incredibly broad. As a result, our knowledge has become very extensive. Whether it's cleaners in clean rooms or heavy duty cleaners that are outside daily in refineries. We are there for every application.

Automotive industry

The Automotive series is specially designed for cleaning and degreasing all types of parts and components in the automotive industry. It achieves excellent cleaning results in many types of materials, especially in complex parts, where our ultrasound produces excellent results thanks to our 28Khz digital synchronized generators.

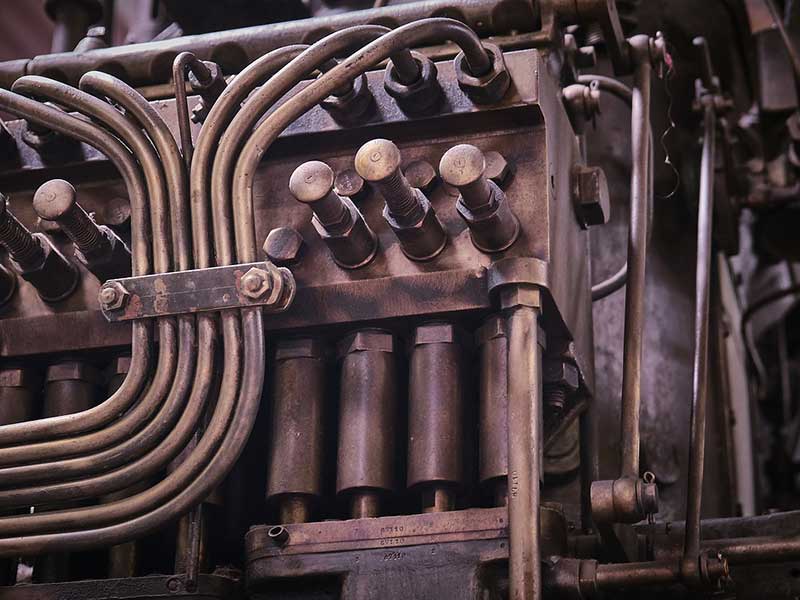

Industrial motors

The large diesel engine industry requires the same specification as the automotive sector, but with a few exceptions, everything is bigger, more robust and a tad more polluted. also for this we have the larger ultrasonic cleaners with unprecedented cavitation power!

Injection molds

Our method for cleaning molds completely removes all residual release agents, oils, greases and materials, such as zamak, aluminum, brass or any type of carbonized plastic or rubber.

Food Industry

ProSonic ultrasonic cleaning equipment not only removes (charred) food residues, but also eliminates microbiological hazards, achieving the best hygiene and safety in the can.

Cleaning in cleanrooms

High end wet surface cleaning, from simple stand alone baths to complex and larger multistage baths and from physical transport automating to datalog systems that work together with you log systems. we offer it to you under one roof.

Discharge

The aggressiveness of our cavitation can make it necessary to work with less violent paint strip chemicals. In fact, you process will get a boost and much more work will be done in a day!

Metalworking

During metal machining, a lot of cool and cutting fluids are used. After machining, these fluids can attract ugly in the new surface structure of the part. To prevent this, direct ultrasonic cleaning is the solution.

Medicinal cleansing

Ultrasonic cavitation kills microorganisms by breaking the cell wall. In conjunction with proper chemicals and a high temperature, it is a powerful formula to kill bacteria such as enterobacteriaceae, Salmonella, Listeria monocytogenes or even Brettanomyces.

Shipping

Equipment from ProSonic is the optimal solution for cleaning any marine element or parts of energy production facilities. Our customized equipment is designed for professional use on board!

Aviation industry

Our exclusive technology is ideal for cleaning hydraulic systems, engine components, injection pumps, vanes and turbines. critical products can be cleaned under monitoring digital data logging.

Printing

No matter how peculiar your printing system may be, and regardless of the quality and printing inks used, ProSonic offers a cleaning solution that breathes new life into your anilox printing rollers. Colors come back to life like never before!

Industrial maintenance

Whether the maintenance is periodic or corrective, the overhaul of parts will have to be done. That is why our industrial line has been developed to always give reliable and desired results.

Automated lines

A subject whose heart beats faster: Automation.

In many processes, the same (type of) part often needs to be cleaned. We can then use various tests to find out under which parameters we can best clean the product/part. This often involves factors such as: ultrasonic power, frequency, chemicals, temperature, cycle time, rinsing, drying, etc. Once everything has been defined, we can design and implement machines that function fully or semi-automatically. By means of various sensors and filter systems we keep a close eye on the quality of the liquid so that production cleaners can run 24/7.

Transporting the parts through the line can be accomplished by overhead crane, robotic arms or conveyor systems.

Projects completed by ProSonic

Marine Maintenance industry

The machine on the left is specially designed

Industrial heat exchangers

The bigger the better, 2 stage 30,000L

Automated rim cleaning