Over 10 years of experience in creative Ultrasonic solutions!

ACM-N Series

Top of the line models

ACM-N Series Ultrasonic Cleaners

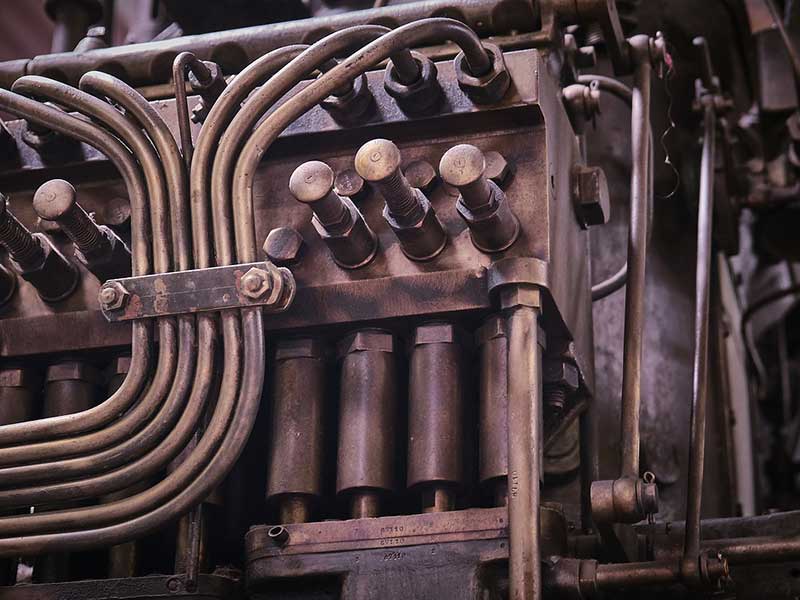

For those who want to go a step further, we have developed the N series. By using 3mm SS304 steel the robust series N ultrasonic cleaner is brought to the market. The ACM-N series is specially designed for the heavy duty workshops thinking of injection molding industry, automotive and maritime sector.

All ProSonic Ultrasonic machines use 28kHz ultrasonic transducer panels with an average power of 5 watts per liter. If a different frequency, higher power or special design is required for your industry ProSonic can provide you with the appropriate customization.

As soon as it comes to a special design, our engineers proceed to the elaboration and visual realization of your wishes. We are happy to take away your worries and realize the a to z process for you.

ACM 170N

- Tank Capacity: 170 Liter

- Ultrasonic power: 1 kW

- Heating: 3.7 kW

- Total power: 4 kW

- Functional dimensions:

- Static load capacity: 50 kg

- Elevator load capacity: 100 kg

ACM 270N

- Tank Capacity: 280 Liter

- Ultrasonic power: 2 kW

- Heating: 7.5 kW

- Total power: 10 kW

- Functional dimensions:

- Static load capacity: 100 kg

- Elevator load capacity: 2500 kg

ACM 350N

- Tank Capacity: 405 Liter

- Ultrasonic power: 3 kW

- Heating: 11 kW

- Total power: 14.5 kW

- Functional dimensions: 1000 x 650 x 620 mm

- Static load capacity: 500 kg

- Elevator load capacity: 250 kg

- External dimensions: 1807 x 1100 x 1735 mm

ACM 500N

- Tank Capacity: 615 Liter

- Ultrasonic power: 4 kW

- Heating: 11 kW

- Total power: 15.6 kW

- Functional dimensions: 1200 x 670 x 530 mm

- Static load capacity: 750 Kg

- Elevator load capacity: 350 Kg

- External dimensions: 2010x1220x1820 mm

ACM 750N

- Tank Capacity: 880 Liter

- Ultrasonic power: 5 kW

- Heating: 11 kW

- Total power: 16.6 kW

- Functional dimensions: 1400 x 800 x 560 mm

- Static load capacity: 1000 Kg

- Elevator load capacity: 500 Kg

- External dimensions: 2270 x 1360 x 1920 mm

Download the specifications here

ACM 1000N

- Tank Capacity: 1280 Liter

- Ultrasonic power: 7 kW

- Heating: 15 kW

- Total power: 22.7 kW

- Functional dimensions: 1600 x 900 x 650 mm

- Static load capacity: 1600 Kg

- Elevator load capacity: 800 Kg

- External dimensions: 2470 x 1490 x 2120 mm

Download the specifications here

ACM 2000N

- Tank Capacity: 2270 Liter

- Ultrasonic power: 9 kW

- Heating: 22 kW

- Total power: 33 kW

- Functional dimensions: 1670 x 980 x 950 mm

- Static load capacity: 2000 Kg

- Elevator load capacity: 1000 Kg

- External dimensions: 2750 x 1830 x 2800 mm

Download the specifications here

ACM 4500N

- Tank Capacity: 5430 Liter

- Ultrasonic power: 15 kW

- Heating: 36 kW

- Total power: 54.8 kW

- Functional dimensions: 2320 x 1500 x 1070 mm

- Static load capacity: 1800 Kg

- Elevator load capacity: 3600 Kg

- External dimensions: 3300 x 2200 x 3600 mm

Download the specifications here

ACM 5500N

- Tank Capacity: 6200 Liter

- Ultrasonic power: 18 kW

- Heating: 45 kW

- Total power: 64 kW

- Functional dimensions: 2620 x 1510 x 1150 mm

- Static load capacity: 5000 Kg

- Elevator load capacity: 1800 Kg

- External dimensions: 3550 x 2250 x 3660 mm

Download the specifications here

ACM 8000N

- Tank Capacity: 9450 Liter

- Ultrasonic power: 27 kW

- Heating: 60 kW

- Total power: 88 kW

- Functional dimensions: 3075 x 1935 x 1260 mm

- Static load capacity: 8000 Kg

- Payload elevator: on request

ACM 12000N

- Tank Capacity: 13550 Liter

- Ultrasonic power: 36 kW

- Heating: 75 kW

- Total power: 112 kW

- Functional dimensions: 4550 x 1900 x 1460 mm

- Static load capacity: 12000 Kg

- Payload elevator: on request

- External dimensions: 5920 x 2890 x 4335 mm

Download the specifications here

CCM 15000N

Based on a 20-foot container

- Tank Capacity: 14440 Liter

- Ultrasonic power: 72 kW

- Heating: 108 kW

- Total power: 186 kW

- Functional dimensions: 4000 x 1900 x 1900 mm

- Static load capacity: 1500 Kg

- Payload elevator: on request

- Rotor system: on request

CCM 25000N

Based on a 40-foot container

- Tank Capacity: 25270 Liter

- Ultrasonic power: 126 kW

- Heating: 189 kW

- Total power: 322 kW

- Functional dimensions: 7000 x 1900 x 1900 mm

- Static load capacity: 2500 Kg

- Payload elevator: on request

- Rotor system: on request

CCM 35000N

Based on a 40-foot container

- Tank Capacity: 36100 Liter

- Ultrasonic power: 180 kW

- Heating: 270 kW

- Total power: 457 kW

- Functional dimensions: 10000 x 1900 x 1900 mm

- Static load capacity: 3000 Kg

- Payload elevator: on request

- Rotor system: on request

Larger machines on request

ProSonic builds and installs machines in all markets!

The sectors in which our customers operate are incredibly broad. As a result, our knowledge has become very extensive. Whether it's cleaners in clean rooms or heavy duty cleaners that are outside daily in refineries. We are there for every application.

Automotive industry

The Automotive series is specially designed for cleaning and degreasing all types of parts and components in the automotive industry. It achieves excellent cleaning results in many types of materials, especially in complex parts, where our ultrasound produces excellent results thanks to our 28Khz digital synchronized generators.

Industrial motors

The large diesel engine industry requires the same specification as the automotive sector, but with a few exceptions, everything is bigger, more robust and a tad more polluted. also for this we have the larger ultrasonic cleaners with unprecedented cavitation power!

Injection molds

Our method for cleaning molds completely removes all residual release agents, oils, greases and materials, such as zamak, aluminum, brass or any type of carbonized plastic or rubber.

Food industry

ProSonic ultrasonic cleaning equipment not only removes (charred) food residues, but also eliminates microbiological hazards, achieving the best hygiene and safety in the can.

Cleaning in cleanrooms

High end wet surface cleaning, from simple stand alone baths to complex and larger multistage baths and from physical transport automating to datalog systems that work together with you log systems. we offer it to you under one roof.

Discharge

The aggressiveness of our cavitation can make it necessary to work with less violent paint strip chemicals. In fact, you process will get a boost and much more work will be done in a day!

Metalworking

During metal machining, a lot of cool and cutting fluids are used. After machining, these fluids can attract ugly in the new surface structure of the part. To prevent this, direct ultrasonic cleaning is the solution.

Medicinal cleansing

Ultrasonic cavitation kills microorganisms by breaking the cell wall. In conjunction with proper chemicals and a high temperature, it is a powerful formula to kill bacteria such as enterobacteriaceae, Salmonella, Listeria monocytogenes or even Brettanomyces.

Shipping

Equipment from ProSonic is the optimal solution for cleaning any marine element or parts of energy production facilities. Our customized equipment is designed for professional use on board!

Aviation industry

Our exclusive technology is ideal for cleaning hydraulic systems, engine components, injection pumps, vanes and turbines. critical products can be cleaned under monitoring digital data logging.

Printing

No matter how peculiar your printing system may be, and regardless of the quality and printing inks used, ProSonic offers a cleaning solution that breathes new life into your anilox printing rollers. Colors come back to life like never before!

Industrial maintenance

Whether the maintenance is periodic or corrective, the overhaul of parts will have to be done. That is why our industrial line has been developed to always give reliable and desired results.

Automated lines

A subject whose heart beats faster: Automation.

In many processes, the same (type of) part often needs to be cleaned. We can then use various tests to find out under which parameters we can best clean the product/part. This often involves factors such as: ultrasonic power, frequency, chemicals, temperature, cycle time, rinsing, drying, etc. Once everything has been defined, we can design and implement machines that function fully or semi-automatically. By means of various sensors and filter systems we keep a close eye on the quality of the liquid so that production cleaners can run 24/7.

Transporting the parts through the line can be accomplished by overhead crane, robotic arms or conveyor systems.

Projects completed by ProSonic

Marine Maintenance industry

The machine on the left is specially designed

Industrial heat exchangers

The bigger the better, 2 stage 30,000L

Automated rim cleaning